More Thermocouple Manufacturers

Thermocouple Applications

Thermocouple assemblies find application across various sectors, including industrial, residential, and commercial uses. They are integral components in a wide array of systems and devices such as water tanks, plastic extrusion machines, heat exchangers, heating equipment, parts washers, kilns, ovens, water heaters, furnaces, pressure chambers, and thermostats.

The History of Thermocouple Assemblies

In 1821, Thomas Seebeck pioneered thermocouples following his discovery of the “Seebeck effect.” Essentially, he found that by joining two different types of metals at both ends and introducing heat at their junction, a minute electric current would traverse the circuit.

Renowned scientists like Michael Faraday and Georg Ohm also explored the Seebeck effect through their experiments in the 1820s, advancing the understanding of this phenomenon among physicists. In 1826, A.C. Becquerel introduced a groundbreaking concept in Paris, proposing for the first time that the Seebeck effect could be employed to measure high temperatures.

In the 1830s, Italian physicist Leopoldo Nobili, alongside Macedonio Melloni, crafted a thermoelectric battery, dubbed the thermo-multiplier. This pioneering creation laid the groundwork for the modern thermocouple. Consequently, some regard Nobili as the father of the thermocouple, heralding his role in its genesis.

Other experts, however, argue that Henry Le Chatelier deserves the title of the father of the thermocouple rather than Nobili. In the waning years of the 19th century, he crafted the inaugural rhodium-platinum and platinum wire thermocouple. Concurrently, American chemists and engineers were also pioneering efforts in thermocoupling. Among these trailblazers was Dr. Carl Barus, who unveiled the linear relationship between couples and concentrated his expertise on temperature measurements for the United States Geological Survey.

After extensive exploration, manufacturers embarked on crafting thermocouples in the early 1900s. As technology evolved, the relevance of these devices in our world has only intensified. Today’s thermocouple assemblies boast exceptional precision and adaptability, marking a significant evolution from their early counterparts.

Thermocouple Design

Production Process

Thermocouple design is elegantly straightforward: they are crafted from two intertwined wires. Additionally, these assemblies are typically encased in an insulating sheath, providing a protective layer that shields the delicate wires within.

To enhance this setup, they equip thermocouples with one of three distinct junction types: grounded, ungrounded, or exposed. Thermocouples with exposed junctions are chosen for their rapid response and swift reading capabilities. These exposed junctions extend beyond their protective sheaths, directly contacting the surrounding environment. Yet, this design is only suitable in environments that are neither pressurized nor corrosive.

Considerations

Thermocouple manufacturers tailor the blend of metals and the calibration of their thermocouple assemblies to suit the specific temperature demands and operational conditions of an application. With these factors in mind, they can craft customized thermocouple assemblies, varying in wire diameters, materials, and other specifications to meet precise needs.

For example, thermocouple wires with slender walls can only withstand a limited temperature spectrum compared to their thicker counterparts. Therefore, if a task demands a wider temperature gamut, the thermocouple should sport more robust wire walls. For applications on surfaces, flat wires are the manufacturers’ choice. Moreover, various metals react uniquely to environmental influences such as mechanical vibrations, abrasions, or chemical exposures; these elements must be considered when crafting a thermocouple. Furthermore, when integrating a thermocouple into an existing system, it is crucial to ensure that its design is compatible with the established components.

Features of Thermocouples

A fundamental thermocouple is made up of two distinct metals joined at their ends, with their tips meeting again and fused into a single bead.

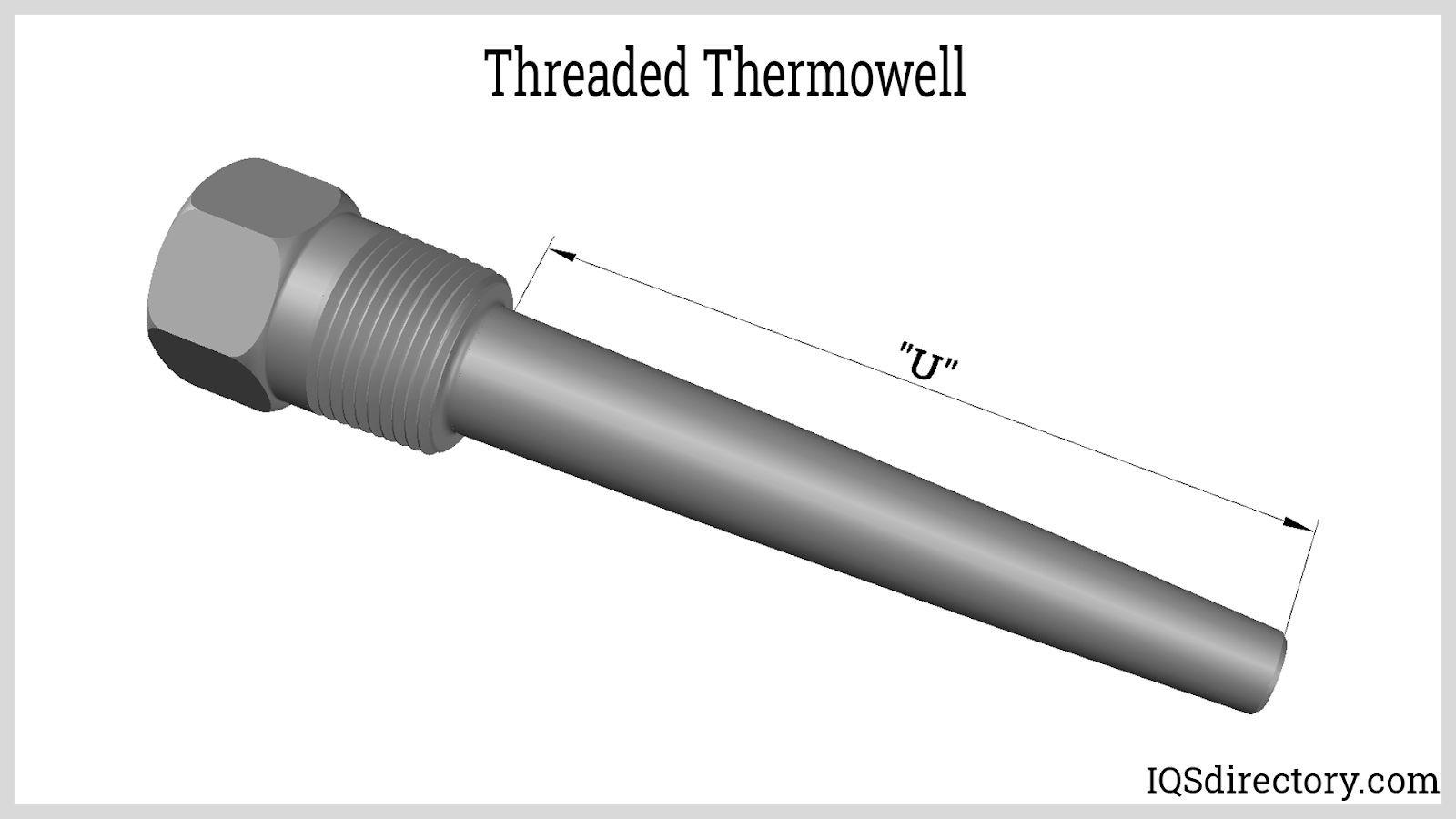

Typically, a team of thermocouples collaborates to capture data that contributes to a more comprehensive measurement. This data frequently interfaces with advanced computer systems that swiftly and precisely digitize it for deeper analysis. In a similar vein, thermocouples often pair with protective accessories like thermocouple wires or thermowells. These additions shield them from the harsh effects of heat and enhance their operational range.

Thermocouples function as temperature sensors, crafted from two distinct metals that converge at one end. This merged endpoint is known as the measurement junction, where the actual temperature reading is taken. The opposite end, remaining separate, is termed the reference junction and needs to maintain a stable temperature to ensure accurate measurements. The Seebeck Effect is the cornerstone of thermocouple technology. This effect unfolds when a temperature difference between two dissimilar metal junctions gives rise to an electromotive force (EMF), which is a blend of Thomson and Peltier EMFs at the unconnected end. This EMF, measured in millivolts, serves as a thermal detective, allowing the precise determination of the temperature in question.

The voltage produced influences the temperature at the reference junction. To maintain the stability of this temperature and enhance the precision of temperature measurements, it is essential to implement cold junction compensation.

Different alloys yield unique voltages, making the choice of metals for a thermocouple crucially dependent on the application’s temperature spectrum and the environmental conditions it will face.

Types of Thermocouples

Thermocouple assemblies fall into two main categories: noble metal thermocouples and base metal thermocouples, each tailored for particular uses thanks to their unique properties. Here are some ways thermocouples are applied:

Noble metal thermocouples, crafted from the esteemed and corrosion-resistant precious metals, withstand the aggressive attacks of chemicals and organic acids. These distinguished devices can accurately measure temperatures up to 2000°C. The noble metal thermocouples encompass types K, N, R, and S, each designed for precision in high-temperature environments.

Base metal thermocouples are crafted from metals other than noble metals. Notable examples include types T and J thermocouples.

Besides these thermocouple assemblies, numerous other classifications exist, often distinguished by their sensitivity. For instance, Type B thermocouples are notably recognized for their minimal sensitivity.

Type K Thermocouple

The Type K thermocouple reigns as the most ubiquitous variant, comprising a duo of alloy strands: alumel, a fusion of aluminum and nickel, and chromel, a blend of chromium and nickel. Known for their robust resistance to high temperatures, Type K thermocouples are a staple in everyday devices.

Type N Thermocouple

Type N thermocouples consist of Nicrosil, a nickel alloy containing 14.4% chromium, and Nisil, which is 95.5% nickel with 4.4% silicon and traces of magnesium. Known for their stability and resistance to oxidation, these thermocouples perform optimally within a temperature range of -454°F to 2372°F. They are engineered to conquer various sources of thermoelectric instability, including gradual or cumulative thermal EMF drift, short-term cyclic fluctuations in thermal EMF upon heating (at temperatures ranging from about 482°F to 1202°F), and time-independent disruptions in thermal EMF.

Type R Thermocouple

Type R thermocouples consist of 13% rhodium paired with platinum. They operate effectively in temperature ranges from 32°F to 2602°F.

Type S Thermocouple

Type S thermocouples, crafted from a blend of platinum and 10% rhodium, are celebrated for their precision, stability, and adeptness in handling high temperatures. They are primarily utilized in the pharmaceutical and biotechnology sectors, although their versatility extends to both low and medium temperature environments as well.

Type T Thermocouple

Type T thermocouples, crafted from copper and constantan, are base metal sensors capable of measuring temperatures up to 1832°F. They are frequently employed in cryogenics and ultra-low temperature freezers due to their resilience at extremely low temperatures. Typically, these thermocouples include materials such as tin, nickel, copper, aluminum, or lead.

Type J Thermocouple

These base metal thermocouples are typically crafted from a combination of iron and constantan. They might also incorporate stainless steel, a robust alloy of iron. Similar to Type T thermocouples, they excel in low temperature environments. However, they can also withstand short durations at high temperatures.

Type C Thermocouple

Type C refractory metal thermocouples, named for their robust composition, are sheathed in materials with exceptionally high melting points. These thermocouples can withstand temperatures exceeding 4712°F, offering the highest level of heat resistance available.

Type E Thermocouple

Type E thermocouples are crafted from a combination of Nickel-Constantan and Nickel-Chromium, making them ideal for applications demanding exceptionally high accuracy.

Thermocouples can be replaced by thermistors and resistance temperature detectors (RTDs), both of which gauge temperature variations by measuring the electrical resistance of specific metals.

Thermistor

Thermistors, crafted from metal oxides, exhibit a unique trait where their resistance decreases as the temperature rises. This makes them part of the “negative temperature coefficient” (NTC) sensor family. Because thermistors can accurately measure temperatures only up to 392°F, they are best suited for low to mid-temperature applications.

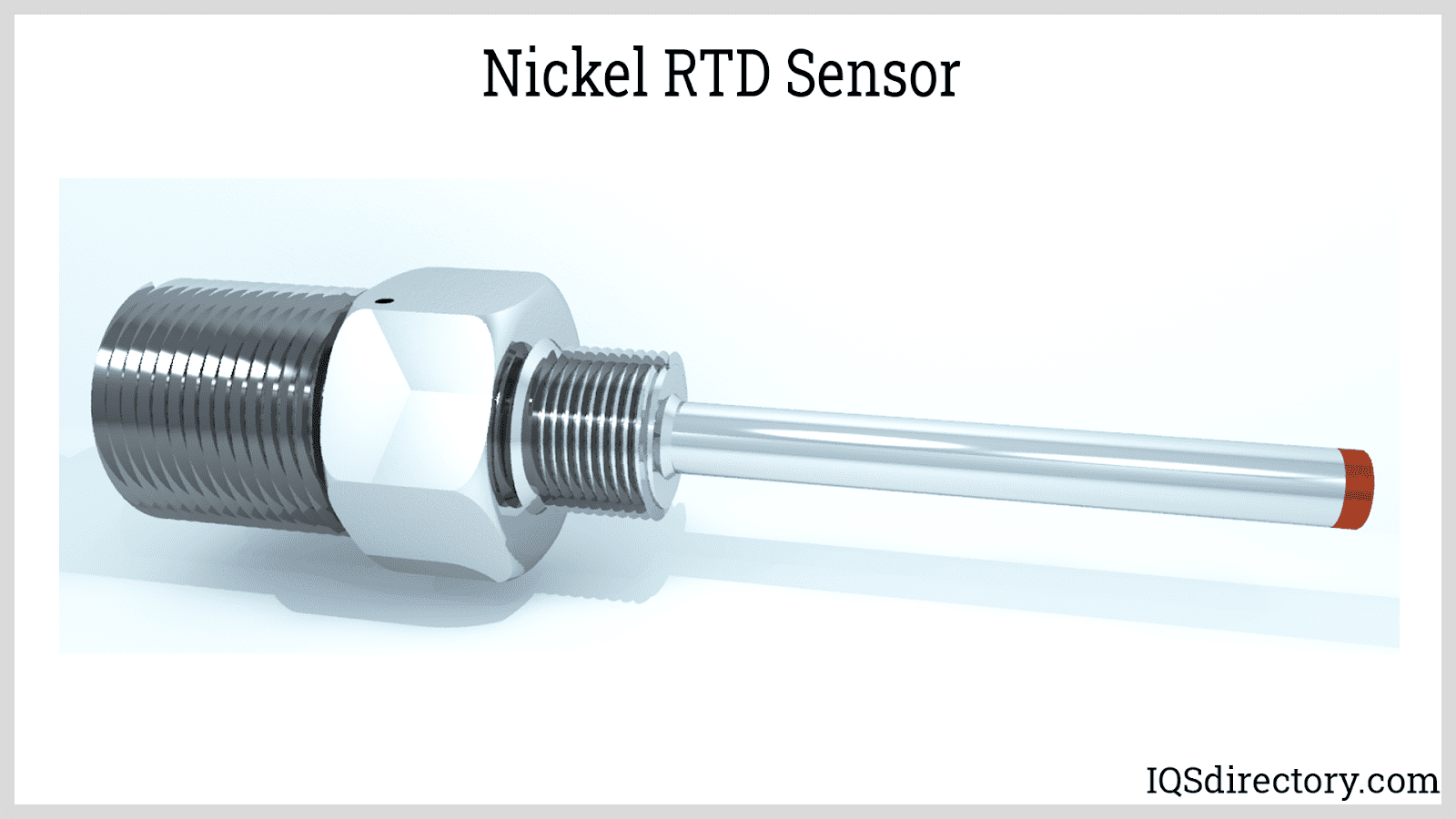

RTD Sensor

For higher temperatures, RTDs are a far superior choice, accurately measuring temperatures between -328°F and 1472°F within a margin of +0.5%. RTDs typically deliver more precise measurements compared to thermocouple assemblies. However, thermocouples offer significantly higher heat capacity and are far more cost-effective to manufacture and use. Both thermocouple and RTD assemblies have their merits, yet thermocouples stand out as the favored choice for temperature measurement. Their simple construction, ease of installation, and affordability make them particularly appealing. Moreover, thermocouples provide rapid response times, clear readability, extensive temperature ranges, and a greater variety of applications compared to thermistors and RTDs.

Advantages of Thermocouple Assemblies

The benefits of thermocouple assemblies are vast and varied: they offer an exceptionally wide range of temperature measurement, deliver precise readings, and are user-friendly. They boast a rapid response time, a straightforward design, and are cost-effective. Additionally, their installation is hassle-free, and they feature intelligent probe design for enhanced performance.

Thermocouple Accessories

Common thermocouple accessories encompass thermocouple wires, temperature transmitters, connectors, thermowells, and isothermal blocks.

Thermocouple wires, often referred to as extension wires, and thermowells serve two primary functions: they shield the thermocouple device from potentially damaging heat sources and extend its operational range. Temperature transmitters relay signals to remote sensing instruments through copper wires, enhancing the efficiency of the thermocouple assembly. Thermocouple connectors provide a swift and effective alternative to traditional terminations. Additionally, isothermal blocks are covers installed inside enclosures to ensure that junctions with varying temperatures remain separate, preserving their respective temperatures.

Proper Care for Thermocouple Assemblies

To ensure your thermocouple assemblies function smoothly, it’s essential to routinely inspect your system for contamination such as corrosion, oxidation, pollutants, or other foreign substances. Neglecting to remove these contaminants can lead to inaccurate readings. Certain pollutants may even interact with your assembly wires, causing corrosion or other alterations.

Be wary of the “Green Rotting Effect.” This phenomenon occurs when a Type K assembly is overstressed and begins to generate thermoelectric voltage. As this voltage builds, it causes the assembly to overheat significantly. With enough heat, the chromium section undergoes oxidation and transforms its structure. Eventually, the thermocouple bond is entirely destroyed, and a green layer forms over the wire. To prevent this, diligently monitor your system and ensure that your thermocouples do not exceed their designed temperature limits.

Standards

Ensuring that your thermocouple assembly is crafted from authentic metals is paramount. These original metal wires, known as thermocouple wire, are essential for maintaining precision and stability. Be certain that your manufacturer uses certified original metals; otherwise, the reliability of your assembly could be compromised.

Industries that Use Thermocouples

Food and Beverage

Thermocouples play a crucial role in the food and beverage manufacturing industry, delivering precise temperature readings essential for various processes such as heating, cooling, frying, and cooking. These sensors are integral to equipment like ovens, warmers, fryers, toasters, grills, and freezers. Given the stringent cleanliness standards in these industries, temperature sensors must adhere to sanitary design requirements to maintain high levels of hygiene.

Power Generation

Type J, K, and N thermocouples are frequently employed in power plants because of their broad temperature range and resilience in harsh conditions. These thermocouples are essential for precise monitoring and management of energy flow within the plants.

Automotive and Aerospace

Thermocouples are crucial for vehicle diagnostics, enhancing engine performance, and boosting vehicle safety. These sensors provide vital temperature readings, essential for monitoring exhaust gases, cylinder heads, spark plugs, and car batteries.

Metal Processing

In the heart of metal foundries, where aluminum, iron, steel, and other metals are forged in the crucible of extreme heat, thermocouples play a critical role. These sensors, like vigilant sentinels, monitor the blistering temperatures that are essential to the metal melting process. Among them, the Types K, N, R, S, and B thermocouples stand out for their ability to endure such fiery environments.

Thermocouples, though simple and cost-effective, offer a vast temperature range and operate independently without needing external power. Their durability, precision, and rapid response time make them indispensable in many applications, ensuring reliable and consistent performance in even the harshest conditions.

Things to Consider Regarding Thermocouples

When searching for a thermocouple assembly, it’s essential to find a high-quality manufacturer. While a subpar supplier might seem cost-effective initially, it will almost certainly end up costing you more in the long run. To avoid these pitfalls, explore the thermocouple assembly manufacturers listed on our site. These manufacturers are industry leaders with excellent track records. Take your time to review their profiles, nestled within this information. As you browse, keep your specifications in mind and consider which manufacturers can best meet your needs. Narrow down your choices to three or four and request quotes from each. Engage in discussions, comparing their services, prices, lead times, and delivery options. Choose the manufacturer you feel most confident in and get started.

Check out our Load Cells website

Check out our Clean Rooms website

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services