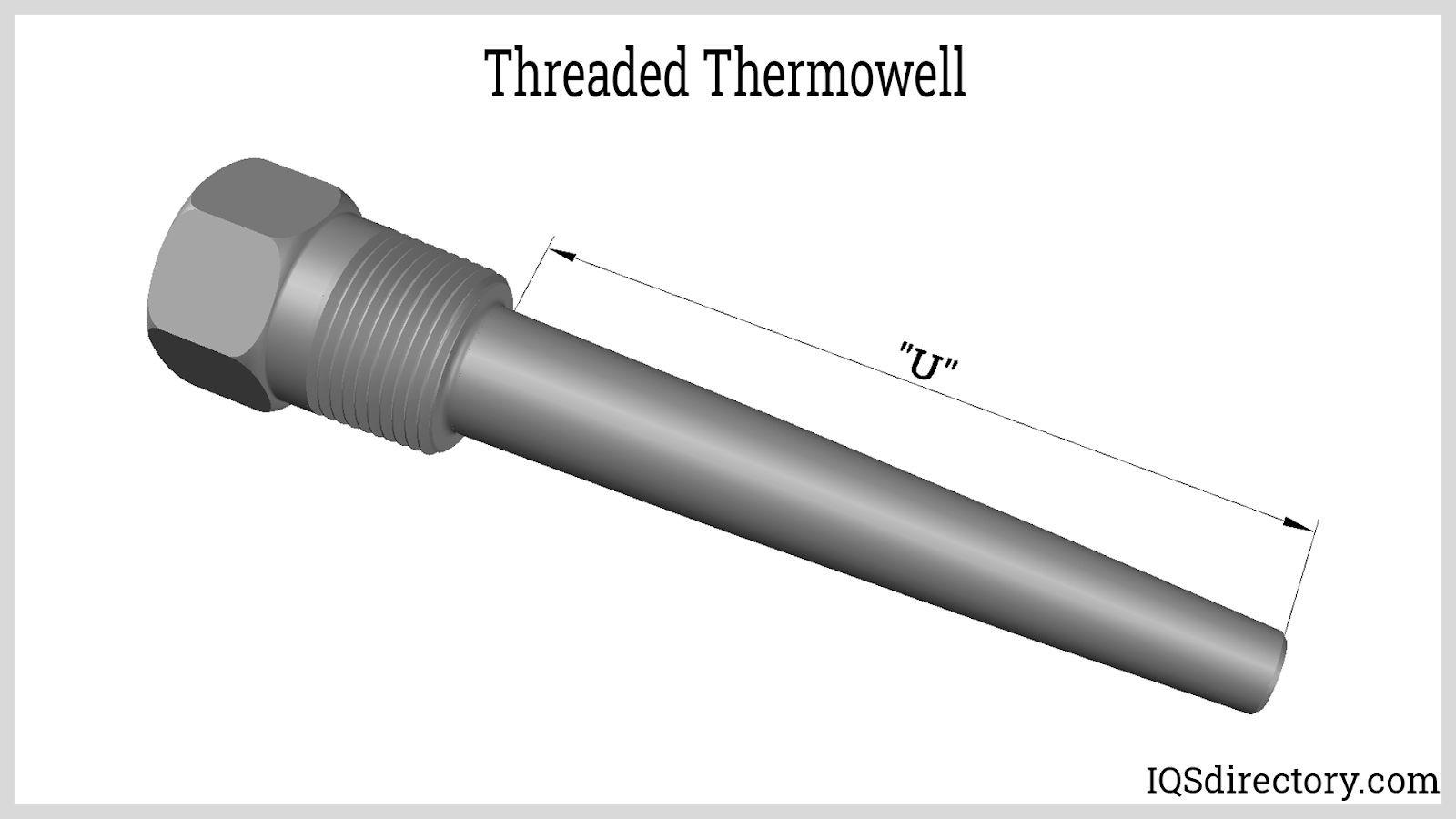

Thermowells and cylindrical fittings protect the temperature sensors deployed in industrial processes. A tube positioned in the product stream, shut at one end, makes up a thermowell. The open end of the tube, which is often outside the process pipework or container and any thermal insulation, is fitted with a temperature sensor, like a thermometer or resistance temperature detector. According to thermodynamics, the process fluid heats the thermowell wall, which then heats the sensor. The well slows the sensor’s reaction to changes in process temperature because there is more mass involved with a sensor-well combination than with a sensor directly submerged in the process. Read More…

In business since 1972, Thermo Sensors Corporation is a leading thermocouple manufacturer of an array of many products and services.

We manufacture a full line of Thermocouples to fit your application. Temperatures from cryogenic to 4000F, and sizes ranging from needle thin to several thousand pound multipoint temperature sensors.

Kelvin Technologies is a high-quality thermocouple manufacturer, representative, and distributor for all of your electrical heating, temperature controlling, and temperature sensing requirements. Our products are engineered and manufactured in-house to address specific requirements, such as higher temperatures and more compact profiles. With over 100 years of combined experience, all of us at...

Temperature Specialists, Incorporated is a manufacturer of quality thermocouples. Temperature Specialists provide solutions for your sensing needs by building to meet your specifications. Feel free to visit their comprehensive and helpful website for full descriptions of their state-of-the-art line of quality products and services or call their experts with any questions.

Since 1971, Thermalogic has been a leading manufacturer of electronic temperature and humidity control and sensors. Here at Thermalogic we work with our clients in a partnership to build a lasting business relationship. All of our products have quick turnaround times, including custom designs, and are thoroughly tested prior to being sent out. At Thermalogic we pride ourselves on our high...

We have over 81 years of successful manufacturing experience and we offer a wide range of solutions. Our thermostats are utilized in industries including HVAC, process heating, food service, laboratory tank heating, industrial system control, and more. We have made it our mission to remain on the forefront of our industry and we work closely with our customers to ensure maximum satisfaction.

More Thermowell Manufacturers

Principle of Operation

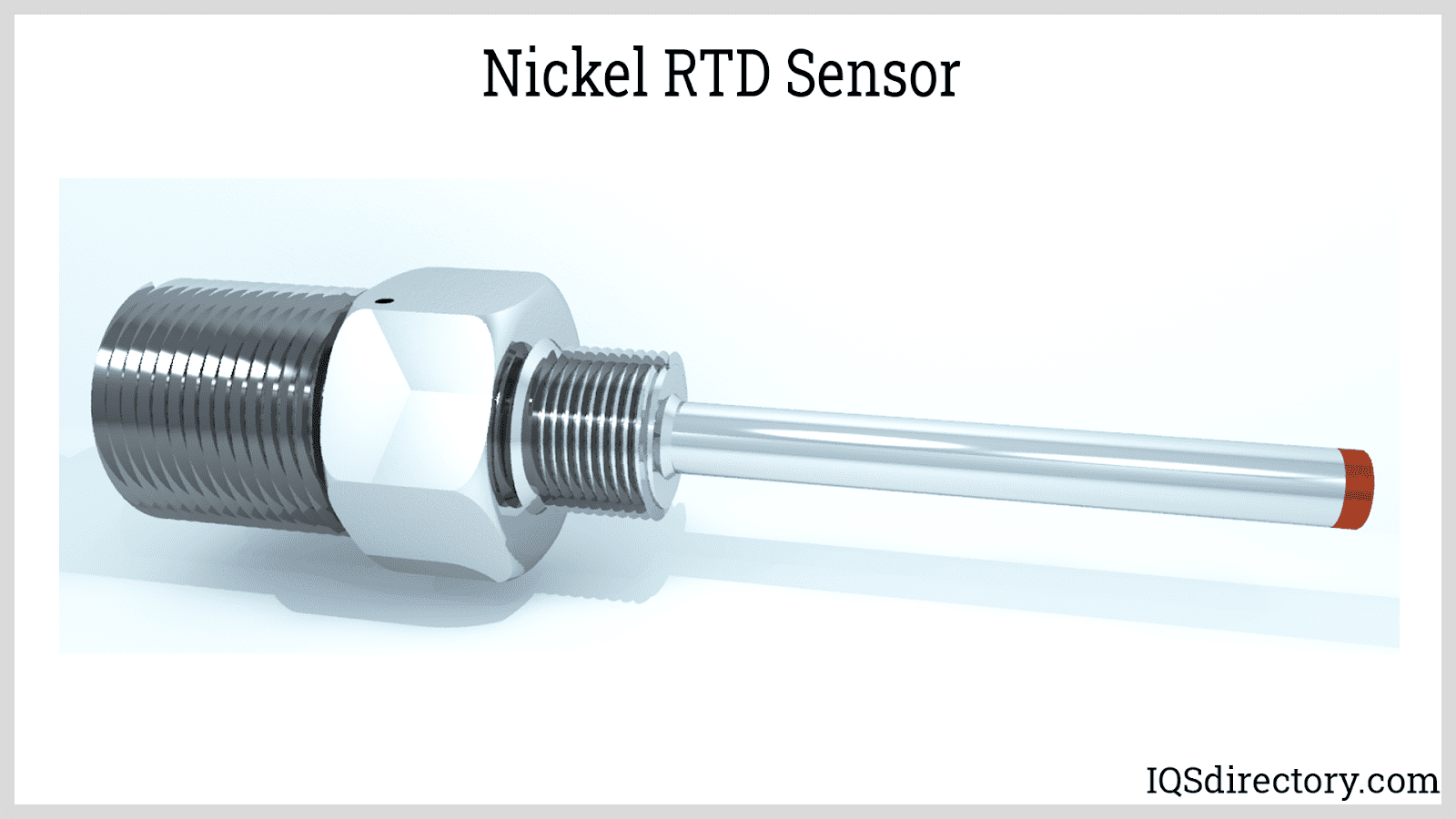

Sensors are inserted inside thermowells through their open end, creating a barrier between the sensors and the surrounding atmosphere. It is usually always spring-loaded when a sensor is inserted into a thermowell, ensuring that its exterior metal tip makes contact with the thermowell's interior metal tip. This metal-to-metal contact ensures that the process fluids' heat transfer to the thermowell wall is transferred to the sensor for it to function. High flow rates, high pressures, and corrosive materials are just a few of the conditions in which they're submerged. Due to the material or atmosphere in which they are being positioned being so incompatible with contact with them, thermocouples frequently cannot function without thermowells. Additionally, thermowells shield sensors against secondary process factors like rust, abrasion, vibration, and mechanical deformation, in addition to the risks associated with physically submerging them into hostile environments and materials.

Types of Thermowells

The shape of the stem determines the type of thermowells. A straight thermowell provides corrosion and erosion resistance by maintaining a constant diameter along the whole length of the insertion. Stepped thermowells typically have a top diameter of 34" and a bottom diameter of 12" near the tip. Reduced surface area enables faster temperature response and smoother velocities for sensor devices. Thermowells are frequently categorized following how they relate to a process.

- Threaded

- Socket welding

- Weld-in

- Flanged

Threaded Thermowell

A threaded thermowell is fitted into the procedure straight into the wall of a plugged pipe through a thermowell thread-out, as the names suggest. It is feasible to detach an instrument with threaded thermowells without losing pressure or process contents. Thermowells additionally guard against the process media bending the instrument. Threaded thermowells are frequently mounted on smaller pipelines or vessels and are ideal for applications requiring infrequent repair. In addition, they function well with non-corrosive media. Thermowells with threads are fabricated from solid hardened steel.

Socket Welded Thermowell

A socket welded thermowell is normally fused into a wall adapter; however, it is also possible to weld a thermowell directly into a pipe wall.

Weld-In Thermowell

Direct welding into the operating vessel or pipe results in a thermowell weld.

Flanged Thermowell

A pipe nozzle's mating flange is joined to a flange collar on a flanged thermowell.

Applications of Thermowells

The applications of thermowells in industrial settings include, but are not limited to: the petrochemical, food processing, cosmetics, refinery, chemicals, power generating, and pharmaceutical industries. Thermowells shield machinery from outside forces and disruptions the processing medium brings, such as abrasion, pressure, vibration, and corrosion. Thermowell-protected devices can be removed and replaced without causing any other environmental harm to the manufacturing space.

Benefits of Thermowells

By improving temperature measurement in numerous ways, thermowells offer an invaluable service. They offer defense against corrosive, rapid material movement and pressure damage. Temperature sensors can be changed using thermowells without depleting the system. In essence, thermowells are used in some sectors to reduce costs. The following is a list of key things to consider while evaluating the cost-savings potential of a thermowell.

- Durability: Sensors can be made in various ways; however, stainless steel probes with a 14" diameter are typically utilized to contain them. This wrapping will offer the sensor excellent protection if the procedure is relatively inert. Nothing else is necessary. On the contrary, some situations where sensing probes are used are openly hostile. Over 1,832 °F (1000 °C) will cause stress on the stainless steel construction, and the sensing probe will distort. For a probe, even the processing medium itself might be taxing. These corrosive materials could be anything from fluids like seawater or acids to solid particles in a gas. The detrimental impacts of extreme temps and corrosive environments are amplified by extreme pressures in a process, acting as a force multiplier.

- Labor costs: Even though the temperature sensor is inexpensive, a thermowell could still be a useful addition. The cost of replacing temperature sensors regularly is labor. They are keeping in mind that the sensors will eventually need to be replaced sensors. When temperature sensors such as RTDs are put into a thermowell, sensor replacement is simple. A worker doesn't require additional protection or equipment since the thermowell seals the operation, preventing outside contamination from entering whenever a temperature sensor changes.

Choosing the Proper Thermowell Supplier

To make sure you have the most positive outcome when purchasing thermowells from a thermowell supplier, it is important to compare at least 5 suppliers using our thermowell directory. Each thermowell supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each thermowell company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple thermowell companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services